Theobroma Cacao

Chocoloate is made from the seeds of Theobroma Cacao trees.

The seeds are called cocoa beans and can be found inside of the fruit, cocoa pods, which grow from the trunks of the trees.

There are approximately 40-50 beans in each pod and each bean is surrounded by a delicious pulp that tastes so tropical!

The pulp is incredibly important in chocolate making because it provides the sugar used in the fermentation process.

Fermentation

Have you ever heard that chocolate contains bugs? This isn't true, but isn't far from the truth.

For thousands of years cocoa farmers have used natural yeast from fruit flies to initiate the fermentation process.

After the beans have been removed from the pods, they are laid out onto tarps so that the fruit flies can land on it and deposit yeast.

The beans are left out for 24 hours, then they are put into cedar fermentation boxes where they will undergo a 2-stage fermentation.

First, the yeast consumes the sugar and turns it into ethanol. Then, acetobacter(the bacteria responsible for vinegar) turns the ethanol into acetic acid(vinegar).

The acetic acid breaks down the cocoa beans, this process is where the flavor compounds are created.

Drying

The drying process is very important. The beans must be reduced to water content of about 6-10%.

The cocoa beans are spread out onto screens in drying sheds, which protect the beans from the weather and give them indirect sunlight.

Traditionally, the drying process takes place in drying houses similar to the ones used today. Ceremonies were performed during this process and cocoa dancers danced in the dry beans to remove the shells.

Roasting

Roasting, is the first part of the process that we do at Gracius Cocoa.

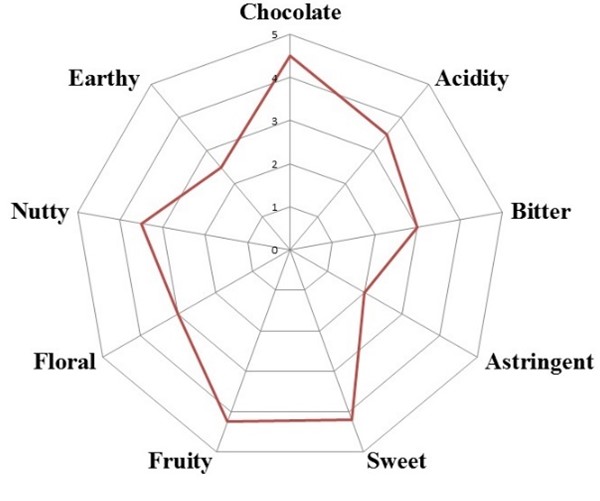

We receive dried beans from the distributor and we roast them to develop a wide variety of flavors in the beans.

Cocoa beans can be roasted using anything that can get hot enough, around 300-400°F. To start our business we are using a normal oven to roast them.

Cracking/Winnowing

After we roast the beans, we crush them in a blender to help separate the shells from the nibs.

The shells are the dried leftover fruit and the seed casing. The nibs are the inner part of the seed that contain the cocoa butter and most of the flavor molecules.

To separate the shells from the nibs, we exploit the difference in density between the nibs and shells through a process called winnowing.

We use a device made from PVC pipes, a bucket and a shop vac that we built ourselves to separate the beans. Ancient people used banana leaves as fans to do the same thing that our device does!

Refining

This is where the magic happens! We use a machine called a melanger to grind the cocoa nibs into chocolate.

The melanger uses two large wheels to grind the cocoa nibs against a heavy plate, this grinding creates heat due to friction which melts the cocoa butter in the nibs.

The longer the cocoa nibs are processed the smaller the particles become, and after 48 hours, the particles begin to collect together and form spiral structures. This spiral formation is called conching.

24 hours before the chocolate is done refining we add the sugar. This gives enough time for the melanger to grind the cocoa nibs without the sugar getting in the way but still allows enough time for it to grind the sugar down so that it is not noticeable.

Molding

After melanging the chocolate, it's time to pour them into the molds and make the bars.

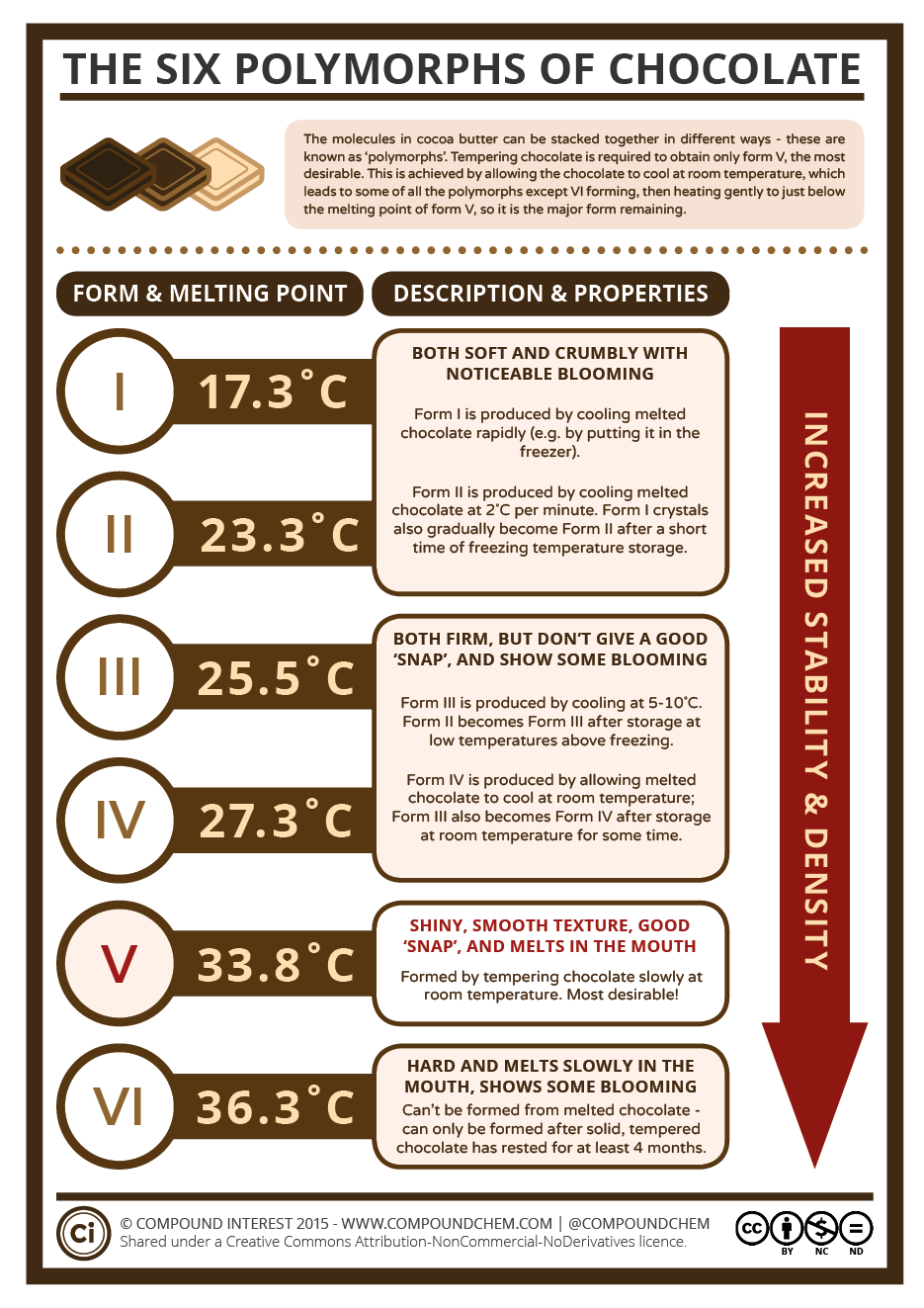

During this process it is important to properly temper the chocolate so that it forms the correct structure.

There are 6 crystal polymorphs. These polymorphs have different characteristics, with type 5 crystals having the most desirable characteristics.

Type 5 crystals have that dark, glossy surface you are used to, with a wonderful snap when you bite it and melt-in-your-mouth experience!